by International Kiteboarding Association 11 Aug 23:02 PDT 18-23 August 2020

Formula Kite Individual Europeans © IKA

Formula Kite Individual Europeans © IKAYears of hard toil to develop a new hydrofoil that will win out in the fight to become the weapon of choice at kiting’s debut at the Paris 2024 Olympics will be put to the test in earnest for the first time at next week’s Formula Kite European Championships in Poland.

From August 10—the day after the 2020 Tokyo Olympics were due to finish—all 10 foils approved by the International Kiteboarding Association’s (IKA) technical committee are eligible for use in Formula Kite competitions as part of the evaluation process lasting until 2021’s close when World Sailing (WS) will license those passing the test.

With the shock withdrawal of the dominant foil of recent years after MikesLab failed to agree to the level of disclosure of construction details required by IKA and provided by all other contenders, the field is wide open for challengers—some established and some new to top-flight Formula Kite racing.

The track at Puck, Poland, will see the newly-approved foils go head-to-head in a highly-anticipated contest offering the first clues of which will emerge on top on the path to Olympic gold on the Games’ Marseille track in the inaugural Formula Kite Mixed Team Relay.

But already, established Austrian Levitaz brand has shown its pace with the innovative R5 and R5-S foils. The stainless-steel fuselage teamed with carbon wings and mast uniquely offers the opportunity to adjust the Angle of Attack (AoA) for changing conditions by quickly altering the rear wing’s cant.

In a Covid-19 disrupted season, France’s Théo de Ramecourt won the sole Hydrofoil Pro Tour stop in La Ventana, Mexico, riding a Levitaz R5 prototype. “I’m carefully optimistic,” said Levitaz’s Adrian Geislinger. “Our philosophy was that we don’t want to do what everyone else does. It must be different. If we copy the others, we won’t be faster or better. The Europeans will be interesting to see what’s out there with all the new manufacturers. It’s exciting.”

Chubanga’s latest V3 foil has earned a strong advance order book. Founder Luca Filippi is delighted that Slovenia’s Toni Vodisek, odds-on favourite for the 2019 IKA KiteFoil World Series until he crashed out injured, sought a V3 for the Europeans after rapturous testing.

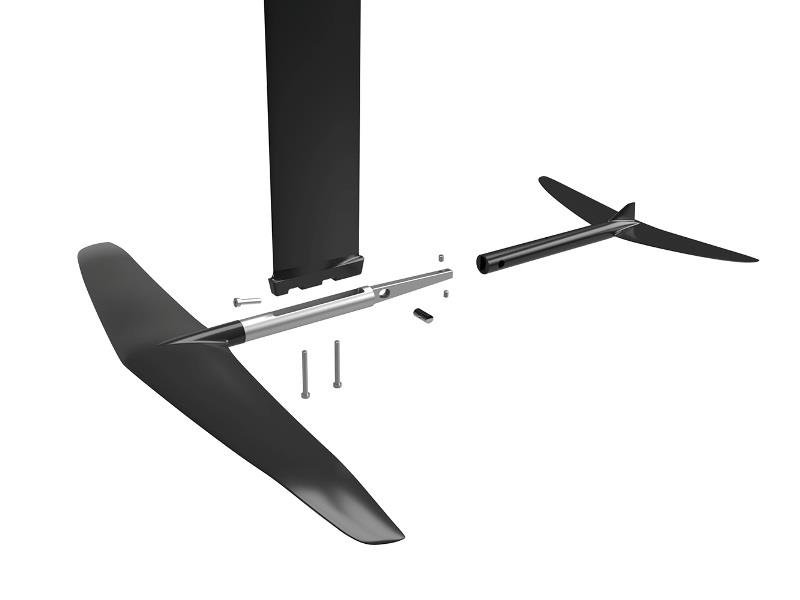

The all-carbon Chubanga V3 has a new mast-to-glider connection for improved strength and ability to alter the AoA, modelled on the MikesLab. “It’s similar to the MikesLab design,” said Filippi. “It’s very intelligent. It’s easier to assemble and possible to change the AoA. The V3 is a step forward. The difference is its maximum speed and acceleration. I was surprised.”

Portugal’s Flying Sardine spent three years perfecting 106cms and 110cms Race Masts and Haze and Flow gliders, helped by the likes of Bulgaria’s Alex Bachev. Brand manager, Florian Trittel, Spanish SailGP team and top foiling Nacra 17 sailor, is confident Flying Sardine’s long, carbon construction experience will prove key.

“There are two key aspects for a foil to be really good: stability and speed,” said Trittel, a former elite kitefoiler. “When you design to go faster, normally it ends up more unstable. So the rider can’t push it to its full potential. Construction is key to achieve stability. There are a few secrets we can’t reveal, but we’re stoked with the results.”

Mainstream kiteboard brands Duotone and Airush-Starboard went with outside designers to craft their all-carbon foils, both with a sole glider and mast. Duotone’s Daytona DOS is a race refinement of the Daytona 105, sacrificing some of that first version’s raw pace for speed around the whole track.

“The Daytona DOS might be a little bit slower, but it’s much faster around the course,” said designer Jerome Bonieux. “Like any brand Duotone would like racers to pick this foil for the Olympics, but it also shows they’re in the game with a race foil. It puts Duotone on the map as a serious foil player. What we learned will trickle down to the rest of the range.”

Airush-Starboard’s Gold designer Craig Chandler gave the 111cm mast’s foot an unusually fine profile to reduce drag. It is supplied with three shim inserts to sit between mast foot and glider. Those allow the native 1.75 degrees AoA to be increased to 2.1 degrees—upping stability but compromising speed by adding drag—or dropped to 1.4 degrees, with the corresponding opposite effects and increased difficulty. “In three or four years’ time we’ve no idea how much stronger and better riders will become,” said Chandler. “It’s important to cater to that.”

A novel construction technique confers optimised and identical bend and twist characteristics to every mast, while the risk of ventilation is reduced by hand-sanding surfaces for a race-ready finish—like many brands. At Element 6 Evolution’s (E6E) Thailand factory, where the Olympic Nacra 17 catamaran foils are fabricated, each Airush-Starboard foil takes 75 man-hours to produce.

Spanish new-comers Uramoztu also coincidentally build at E6E, believing it the “best” after unsatisfactory trials in Europe and Asia. Formed three years ago to make “the fastest foil in the market”, it poured resources into developing software to simulate the forces acting on its hydrofoil designs before a shortened testing period. Uramoztu’s Alfredo Revuelta said it teamed its 105cm Race Master mast with three gliders “adapted to different riders’ weights and heights, making crucial differences that we saw on the computer.”

To reduce costs Taaroa, an early kitefoil leader with its legendary Sword 2, also builds its new foil at its dedicated Thailand facility. But the French brand, under new ownership, has big ambitions for its Sword 108 UHM, with its titanium fuselage, and carbon wings and mast. They are built with new manufacturing techniques that achieve unprecedented “rigidity and stability”, according to Taaroa’s Baptiste Tripard. “We’re very proud for two reasons: we achieved ultra-performance, surpassing previous generations. But it’s also progressive: performance for consumers. It’s not a small series only for professional riders, but people who want to go fast.”

Established brands Enata and KiteFoil Australia (KFA) both build in the United Arab Emirates. At its own factory, Enata teamed its existing 112cm MG mast with a new Katana glider that ditched earlier downturned tips prone to ventilation when the wings breached. “We’ve been working on the glider for some time,” said Mateo Veiujot, kite division chief. “Now the back wing sweeps up smoothly, while the front wing goes down, then comes up a little. We got a lot more performance.”

In refining its Mako 4 foil, kite race pioneers KFA found itself ousted from its Auckland, New Zealand, contract producer in favour of more lucrative 2021 America’s Cup work and decamped to UAE. “That business brings much more money for them,” said KFA’s Marvin Baumeister. “Ours are the smallest parts, but the hardest to make with all the Olympic regulations. It’s like rocket science. But at least it should show on the race track. We were looking for accessible performance for really good riders. We think we got it.”

Perhaps the biggest foil brand, Italy’s Moses had no production issues. Proudly made in director Jimmy Mazzanti’s home town of San Mauro Pascoli, near Rimini, the modular K106-670 was the first foil approved by the IKA. “The inspection process for us was a big job,” he said. “It was very detailed. But I think we’ve got a very competitive foil and it was worth it. The potential’s huge with the Olympics and all the [World Sailing] MNAs [Member National Authorities] needing foils for their young athletes.”

Recent Comments